Torpedo Flex-Hose

Torpedo Flex Hose minimizes lead exposure from flex hoses stored aboard submarines. The Navy has established strict controls to limit both occupational and environmental exposures to lead. A tin-plated lead tape is used within the Flex-Hose as a ballast to prevent entanglement with the guidance wire when deployed. The tin-plated lead tape can breakdown, exposing sailors to lead dust.

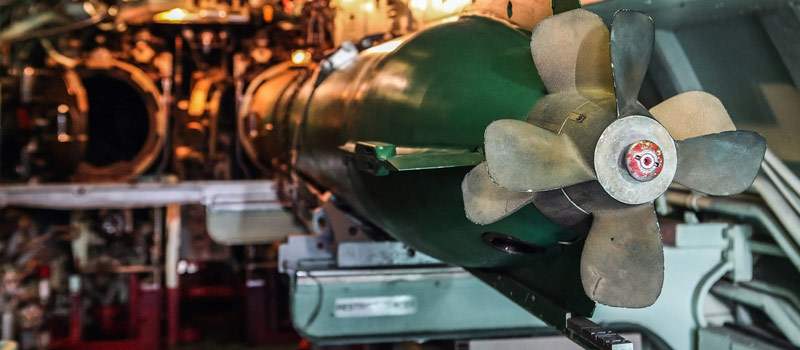

The Flex-Hose is used to position the guidance wire below the submarine’s keel and clear of the propellers. A lead tape ballast is used within the Flex-Hose to make it heavy enough so that the submarine can travel through the water at high speeds without the guidance wire entangling with its propeller. At the end of the torpedoes run the flex-hose is expended into the ocean. The new ballast tape is encapsulated with LDPE to minimize production cost and protect the sailor and the environment. In addition to cost advantages, this approach had minimal impact on the current manufacturing process of the Flex Hose assembly.

For more detailed questions, feel free to contact us.

Click here for more information on Flex-Hose and to be taken to the TRI Austin Site